Understanding CNC Machines

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry, enabling precise and efficient production of a wide range of products. Whether you are a beginner or an experienced operator, learning how to use a CNC machine is essential to maximize its potential. This guide will take you through the important aspects of using a CNC machine, from basic operation to advanced techniques.

Basic Operation

Before diving into the intricacies of CNC machine operation, it is crucial to understand the basics. A CNC machine is controlled by a computer program, which converts design files into numerical instructions. These instructions are then executed by the machine, resulting in the production of the desired object. To use a CNC machine:

- Prepare the design file: Use computer-aided design (CAD) software to create or import the design file. Ensure the file is compatible with the CNC machine's software.

- Set up the machine: Secure the material to be machined on the CNC machine's worktable. Make sure it is properly aligned and clamped to prevent movement during operation.

- Load the design file: Transfer the design file to the CNC machine's computer. Follow the machine's instructions for loading the file, which may involve using a USB drive or establishing a network connection.

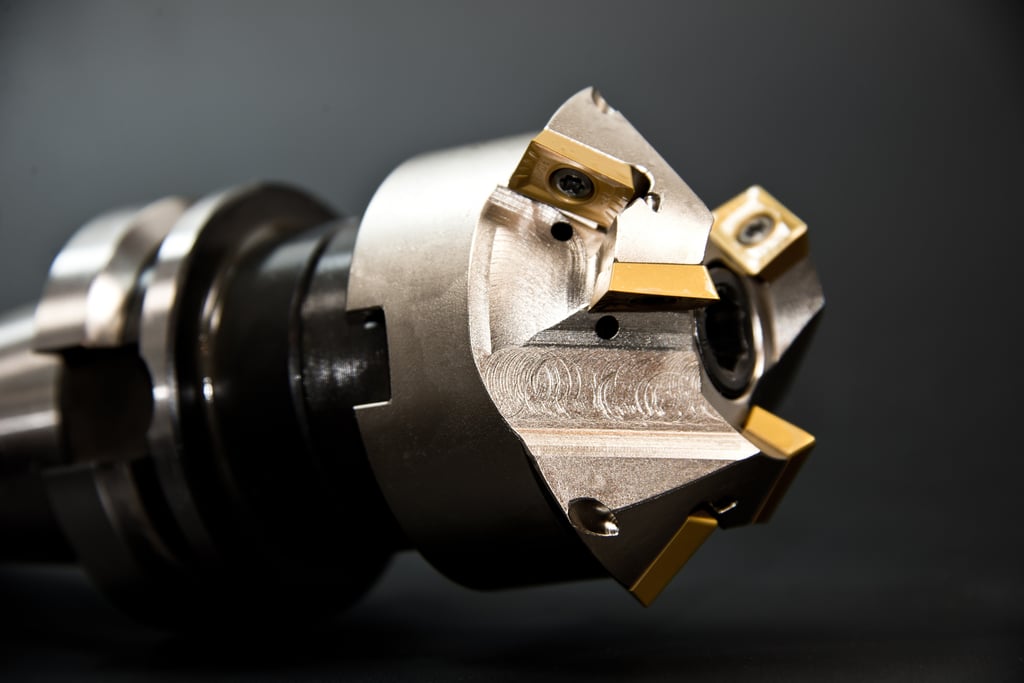

- Configure machine settings: Depending on the material and desired outcome, adjust the machine settings such as spindle speed, feed rate, and tooling. Consult the machine's manual for specific instructions.

- Run the program: Once the design file is loaded and the machine is properly configured, initiate the program. The CNC machine will execute the instructions, cutting, drilling, or shaping the material as per the design.

- Monitor the operation: Keep a close eye on the machine during operation to ensure everything is running smoothly. Be prepared to intervene in case of any issues or emergencies.

- Post-processing: Once the CNC machine has completed its operation, carefully remove the finished product from the worktable. Perform any necessary post-processing, such as sanding or polishing, to achieve the desired result.

Advanced Techniques

While the basic operation of a CNC machine covers the essential steps, there are several advanced techniques that can enhance your machining capabilities:

Toolpath Optimization

Toolpath optimization involves determining the most efficient route for the machine's cutting tool to follow. By optimizing the toolpath, you can minimize machining time, reduce tool wear, and enhance overall productivity. Various software programs and algorithms can assist in generating optimized toolpaths.

Multi-axis Machining

CNC machines often offer multi-axis capabilities, allowing for more complex and intricate machining operations. By utilizing additional axes, such as the fourth or fifth axis, you can achieve greater precision and versatility in your machining projects.

Fixture Design

A well-designed fixture is crucial for securely holding the workpiece during machining. Consider factors such as clamping mechanisms, accessibility, and material support when designing fixtures. A properly designed fixture ensures accurate and repeatable machining results.

Safety Precautions

Operating a CNC machine requires strict adherence to safety protocols to protect yourself and others from potential hazards. Here are some essential safety precautions to follow:

Proper Training

Receive thorough training on how to operate a CNC machine before attempting to use it. Familiarize yourself with the machine's manual, safety guidelines, and emergency procedures. Do not operate the machine if you are unsure of any aspect.

Personal Protective Equipment (PPE)

Always wear appropriate PPE, including safety glasses, ear protection, and gloves, when operating a CNC machine. Ensure loose clothing and jewelry are secured to prevent entanglement with moving parts.

Maintenance and Inspection

Regularly inspect the CNC machine for any signs of wear, damage, or malfunction. Follow the recommended maintenance schedule provided by the manufacturer to keep the machine in optimal working condition.

Adequate Ventilation

When using a CNC machine, ensure the workspace is well-ventilated to prevent the buildup of dust and fumes. Dust collection systems and proper ventilation help maintain a safe and healthy working environment.

Emergency Stop Button

Familiarize yourself with the location and operation of the emergency stop button on the CNC machine. In case of an emergency or unexpected situation, press the emergency stop button to immediately halt the machine's operation.

Conclusion

Mastering the art of using a CNC machine opens up a world of possibilities in the field of manufacturing. By following the basic operation steps, exploring advanced techniques, and prioritizing safety, you can harness the full potential of this powerful tool. Remember to always consult the machine's manual and seek proper training before operating a CNC machine.