The Importance of Nozzle Distance for 3D Printing

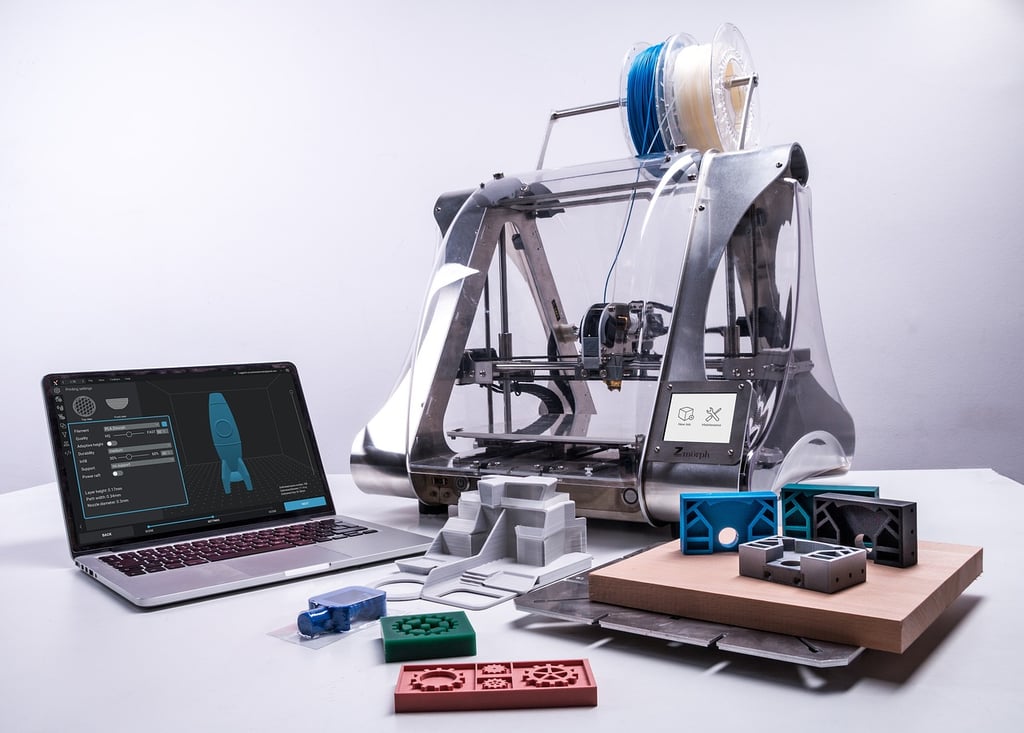

When it comes to 3D printing, achieving high-quality results relies on various factors, one of which is the nozzle distance. The distance between the nozzle and the print bed plays a crucial role in determining the success of a print. In this article, we will explore the best nozzle distance for 3D printers and how it impacts the overall printing process.

Understanding Nozzle Distance

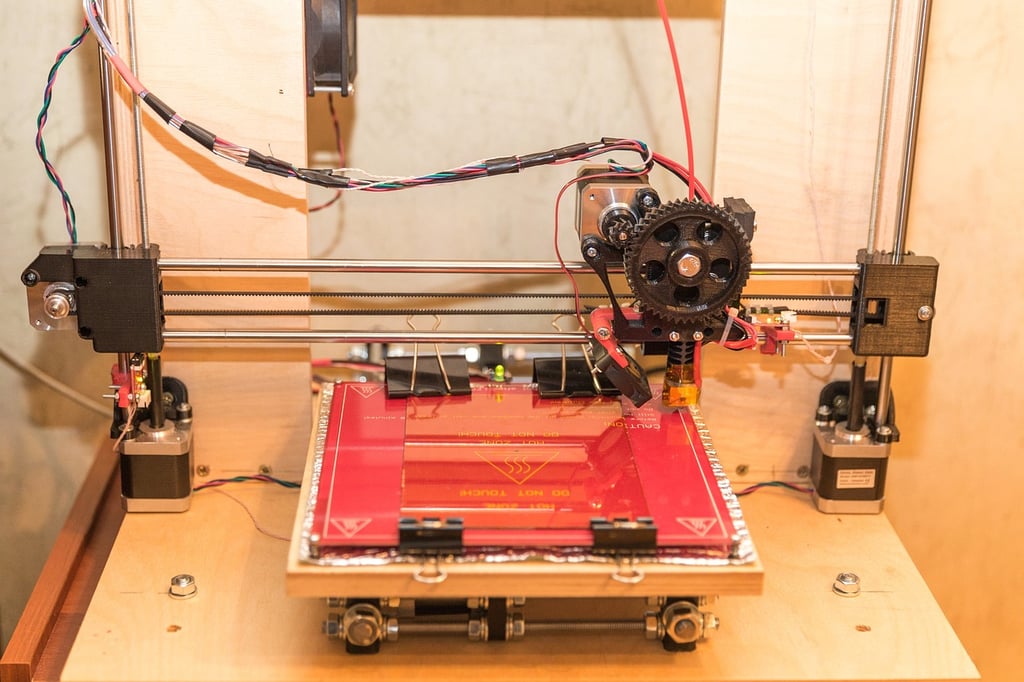

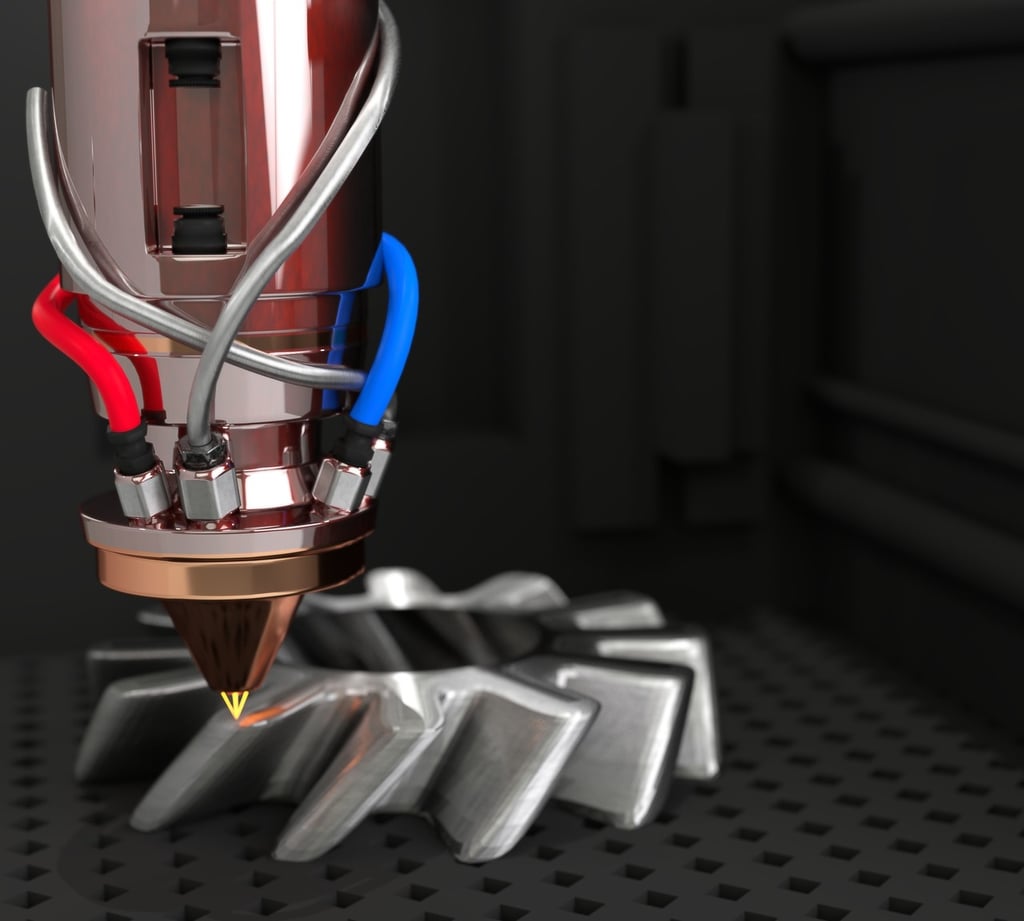

Nozzle distance refers to the gap between the nozzle of the 3D printer and the print bed. This distance is essential because it determines the accuracy, adhesion, and overall quality of the printed object. Finding the optimal nozzle distance is crucial for ensuring successful prints and avoiding potential issues that may arise from incorrect settings.

Factors Affecting Nozzle Distance

Several factors influence the ideal nozzle distance for 3D printing. Let's take a closer look at each of them:

1. Print Bed Leveling

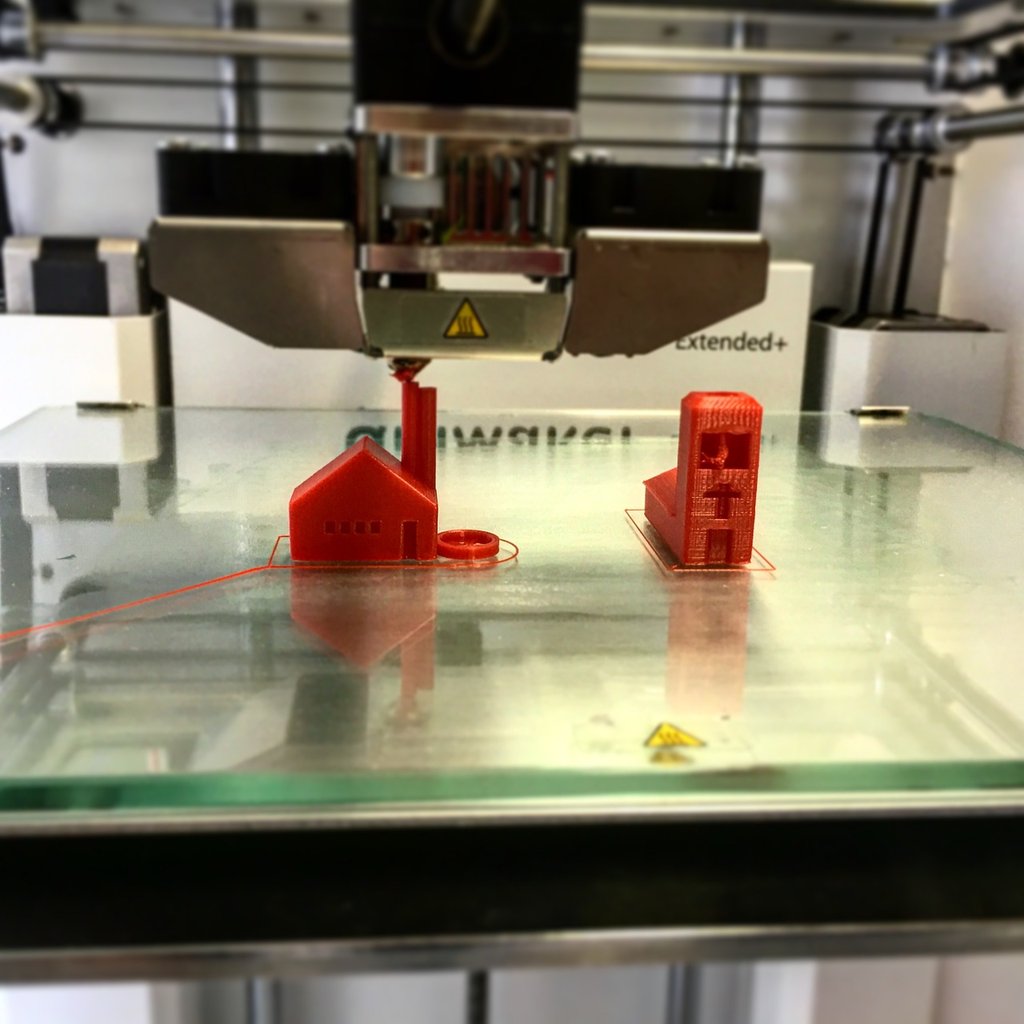

Properly leveling the print bed is the first step towards achieving the best nozzle distance. Uneven or tilted print beds can lead to inconsistent nozzle distances across the bed, resulting in uneven prints or failed adhesion. Ensuring that the print bed is perfectly level is crucial for maintaining a consistent nozzle distance throughout the print.

2. Filament Type and Diameter

The type and diameter of the filament being used also influence the optimal nozzle distance. Different filament materials have varying properties, such as viscosity and flow characteristics. These properties can affect the required nozzle distance for optimal extrusion. Additionally, filament diameter plays a role in determining the ideal nozzle distance, as thicker filaments may require a slightly larger gap to allow for proper material flow.

3. Nozzle Size

The size of the nozzle itself is another factor to consider when determining the best nozzle distance. Nozzles come in various sizes, ranging from small diameters (e.g., 0.2mm) to larger ones (e.g., 0.8mm). The nozzle size directly affects the amount of material being extruded and, consequently, the required nozzle distance. Larger nozzles may require a slightly larger gap to accommodate for the increased material flow.

4. Printing Speed

The printing speed also plays a role in nozzle distance. Faster print speeds require a smaller nozzle distance to ensure that the material is properly deposited on the print bed without causing issues like under-extrusion or missed layers. Slower print speeds, on the other hand, may allow for a slightly larger nozzle distance without compromising print quality.

Finding the Optimal Nozzle Distance

Now that we understand the factors influencing the nozzle distance, let's discuss how to find the optimal distance for your 3D printer:

1. Manual Calibration

One way to determine the best nozzle distance is through manual calibration. This involves adjusting the nozzle height while the printer is in operation. Begin by setting the nozzle distance slightly higher than the desired distance and gradually lower it until the extruded filament adheres properly to the print bed. This process may require some trial and error, but it allows for precise adjustments based on the specific printer and filament being used.

2. Automatic Bed Leveling

Many modern 3D printers come equipped with automatic bed leveling features. This technology uses sensors to measure the distance between the nozzle and the print bed at multiple points and automatically adjusts the nozzle height accordingly. Automatic bed leveling can greatly simplify the process of finding the optimal nozzle distance, particularly for beginners or those using printers with complex bed designs.

3. Manufacturer Guidelines

Consulting the manufacturer's guidelines or documentation can provide valuable insights into the recommended nozzle distance for your specific printer model. Manufacturers often provide recommended settings and nozzle distances based on extensive testing and research. While these guidelines can be a great starting point, keep in mind that fine-tuning may still be required based on your unique printing setup.

Conclusion

The nozzle distance is a critical parameter that significantly impacts the quality and success of 3D prints. By considering factors such as print bed leveling, filament type, nozzle size, and printing speed, you can find the optimal nozzle distance for your 3D printer. Experimentation, calibration, and following manufacturer guidelines are key to achieving the best results. Remember, finding the sweet spot for nozzle distance can significantly enhance the overall printing experience and ensure impressive, high-quality prints.

Relative Articles

-

What is an Extruder in 3D Printing?

-

Is 3D Printing Hard? Exploring the Prospects of This Innovative Technology

-

How to Remove Raft from 3D Print: A Step-by-Step Guide

-

How to Clean Up Stringing on 3D Print

-

How to Calibrate Your 3D Printer for Optimal Performance

-

Can I Pause a 3D Print Overnight? Exploring the Pros and Cons

-

How to 3D Print Large Objects

-

How to Recycle 3D Printer Filament: A Comprehensive Guide