Understanding Stringing in 3D Printing

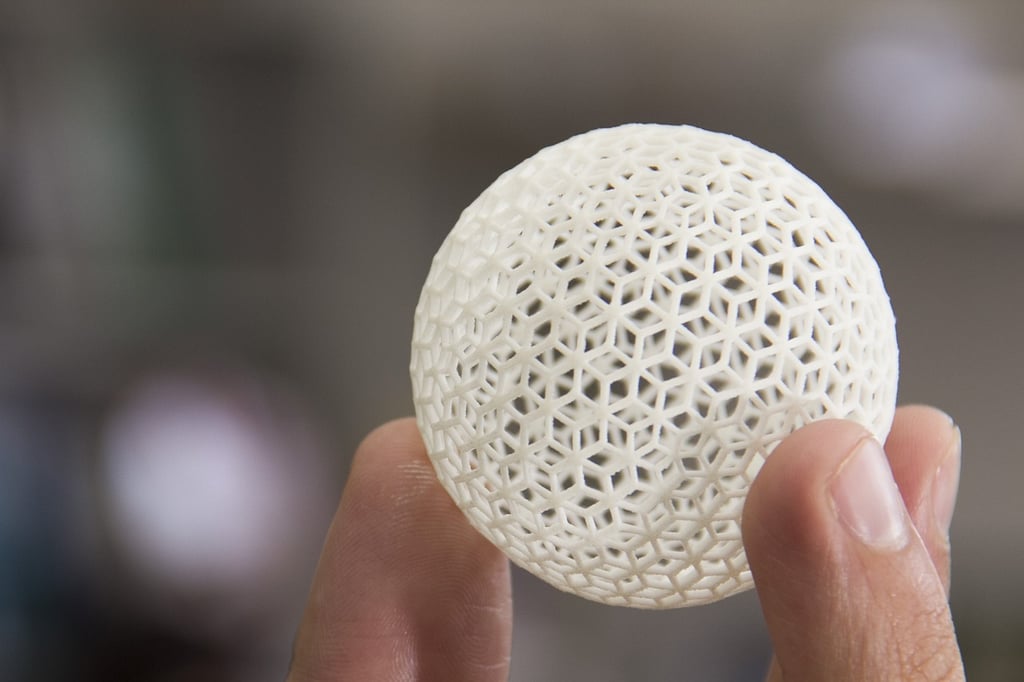

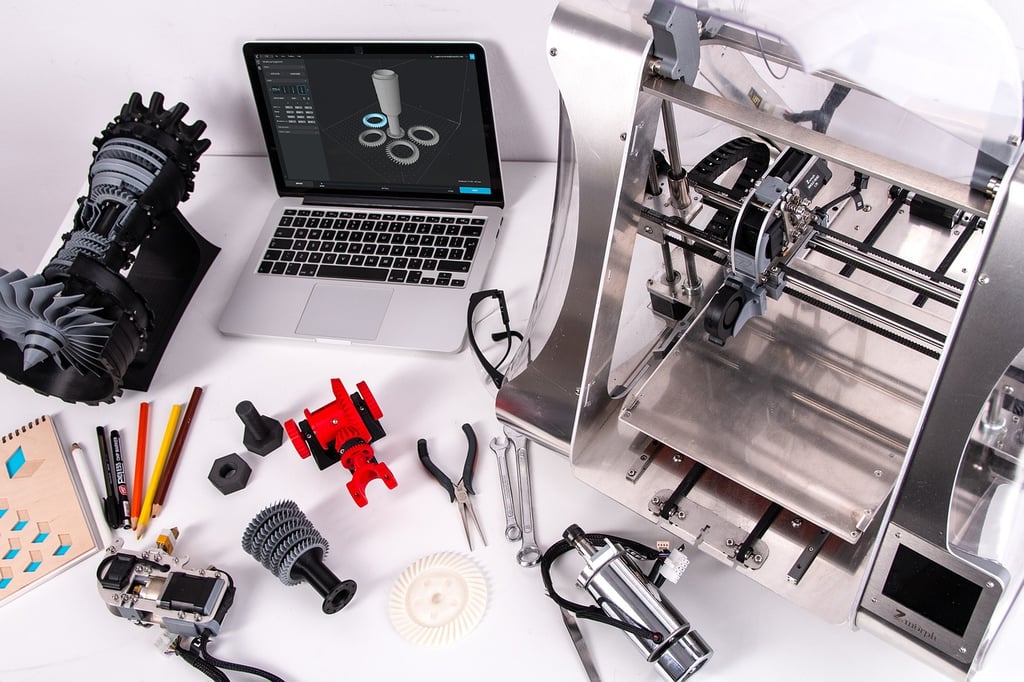

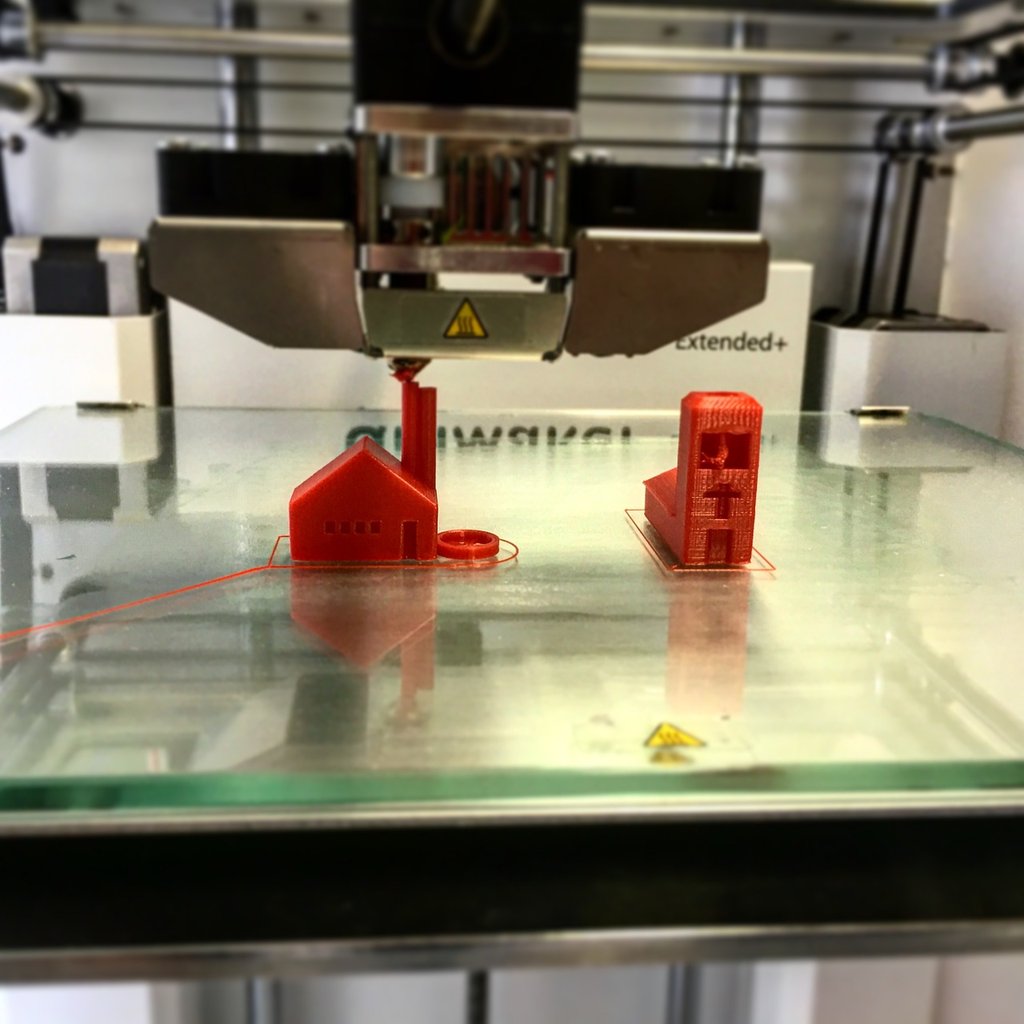

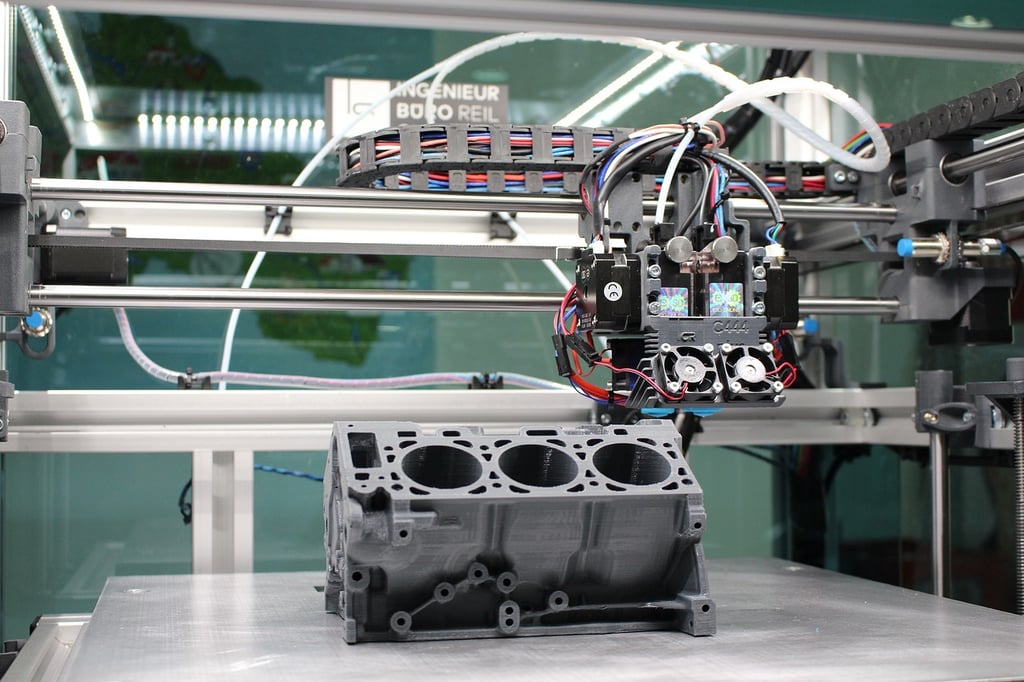

Stringing is a common issue that occurs during 3D printing, where thin strands of filament are left behind between different parts of the printed object. This can negatively affect the overall quality and appearance of the print. However, with the right techniques and settings, you can effectively clean up stringing on your 3D prints and achieve smoother, more polished results.

Optimizing Retraction Settings

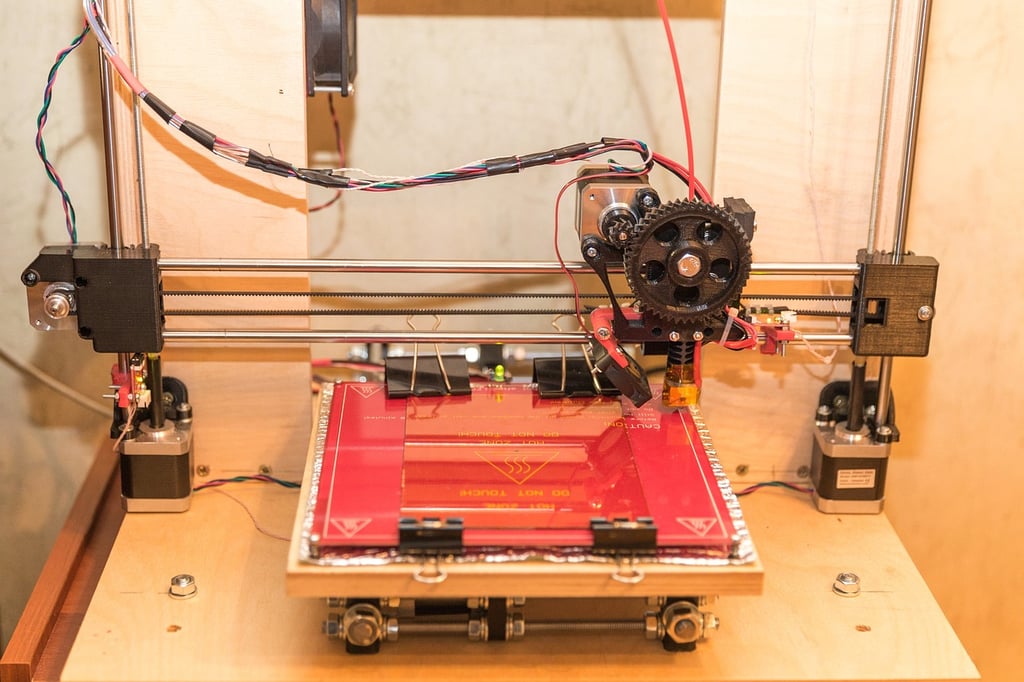

One of the key factors that contribute to stringing is improper retraction settings. Retraction is the process by which the printer pulls the filament back slightly to prevent oozing between movements. By adjusting the retraction settings, you can minimize the occurrence of stringing. Start by increasing the retraction distance, typically around 1-2mm, and gradually fine-tune it until the stringing is reduced. Additionally, adjusting the retraction speed can also help in preventing stringing, so experiment with different speeds to find the optimal setting for your specific printer and filament.

Temperature Control

Another factor that can influence stringing is the temperature at which the filament is extruded. Higher temperatures tend to make the filament more fluid, increasing the likelihood of oozing and stringing. Lowering the printing temperature can help reduce stringing, but be cautious not to go too low as it may negatively impact print quality. Experiment with small temperature adjustments, typically in 5-degree increments, until you find the sweet spot where stringing is minimized without compromising the overall print quality.

Using Retraction Towers

Retraction towers are specialized structures that can be added to your 3D print to help clean up stringing. These towers are printed alongside the main object and consist of a series of vertical walls at different heights. The idea is that the printer will perform retraction and extrusion tests on these towers, purging any excess filament and reducing stringing in the main print. Many slicing software programs have built-in features for generating retraction towers, so make sure to explore these options and utilize them when necessary.

Utilizing Z-Hop and Coasting

Z-hop and coasting are two advanced techniques that can further help in cleaning up stringing on 3D prints. Z-hop refers to the printer lifting the nozzle slightly when moving between different parts of the print. This prevents the nozzle from dragging across the printed object, reducing the chances of stringing. Coasting, on the other hand, involves stopping the extrusion just before reaching the end of a movement, allowing the pressure in the nozzle to naturally complete the extrusion. Both techniques can be enabled in your slicer software and should be fine-tuned to find the optimal settings for your specific print.

Post-Processing Techniques

If you still notice some residual stringing after applying the above techniques, there are post-processing methods you can try to clean up the final print. One common method is to use a heat gun or a hairdryer to gently heat the affected areas and carefully remove the excess strings. Another option is to use a small handheld tool, like a hobby knife or tweezers, to manually cut and remove the strings. Be cautious when using any sharp tools to avoid damaging the print. Additionally, sanding or filing the surface of the print can help smooth out any remaining imperfections caused by stringing.

Relative Articles

-

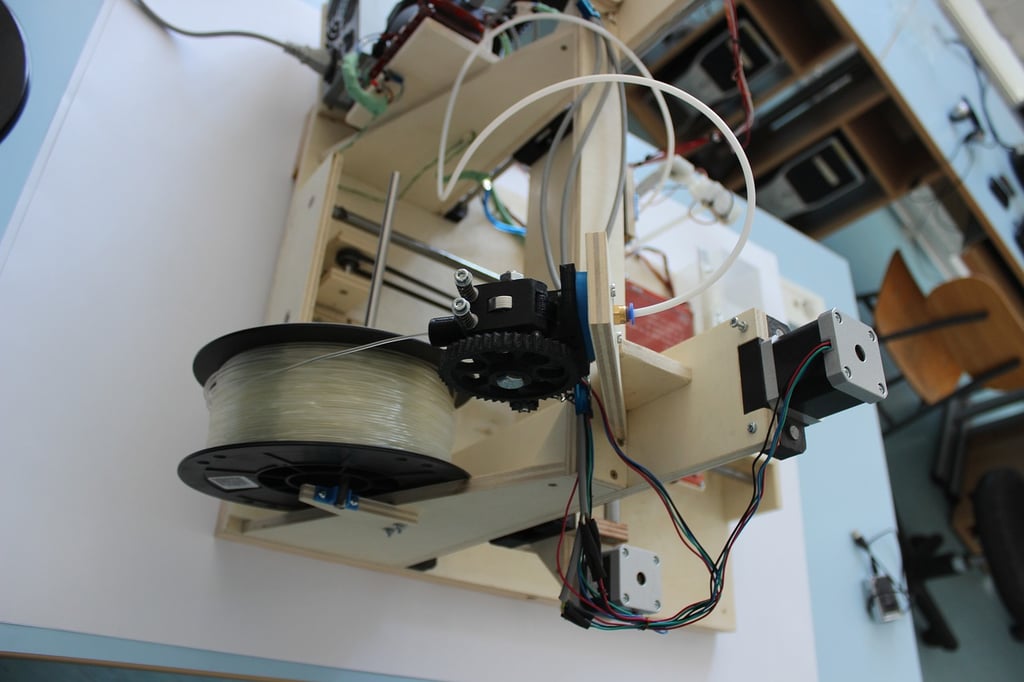

What is an Extruder in 3D Printing?

-

Is 3D Printing Hard? Exploring the Prospects of This Innovative Technology

-

How to Remove Raft from 3D Print: A Step-by-Step Guide

-

How to Calibrate Your 3D Printer for Optimal Performance

-

Can I Pause a 3D Print Overnight? Exploring the Pros and Cons

-

How to 3D Print Large Objects

-

How to Recycle 3D Printer Filament: A Comprehensive Guide

-

How to Make 3D Printer Filament from Plastic Bottles