Understanding the Importance of Calibration

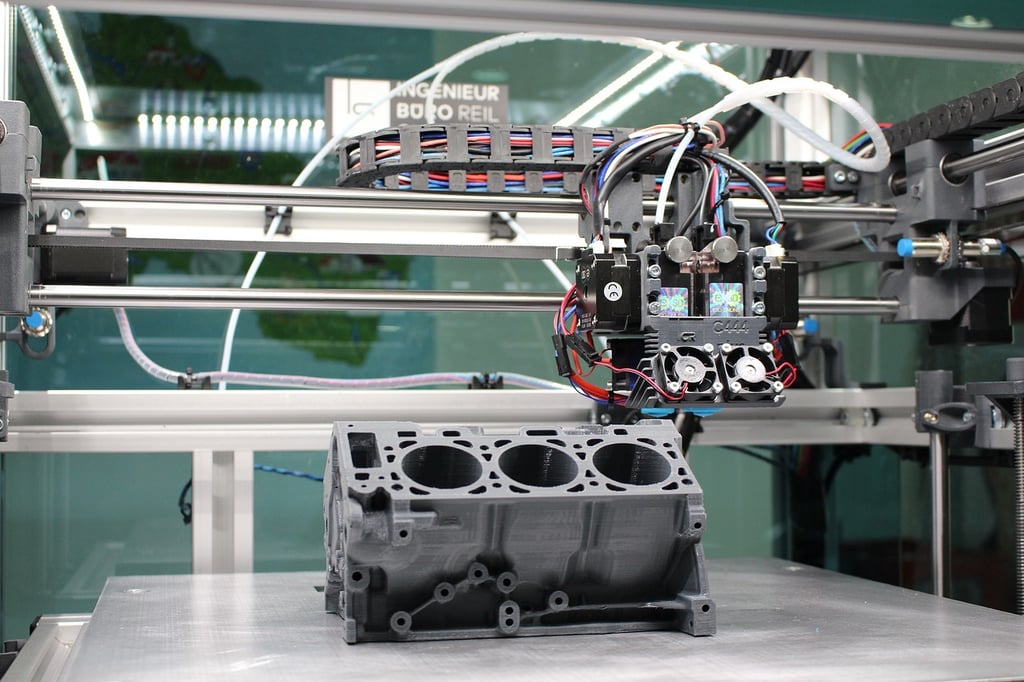

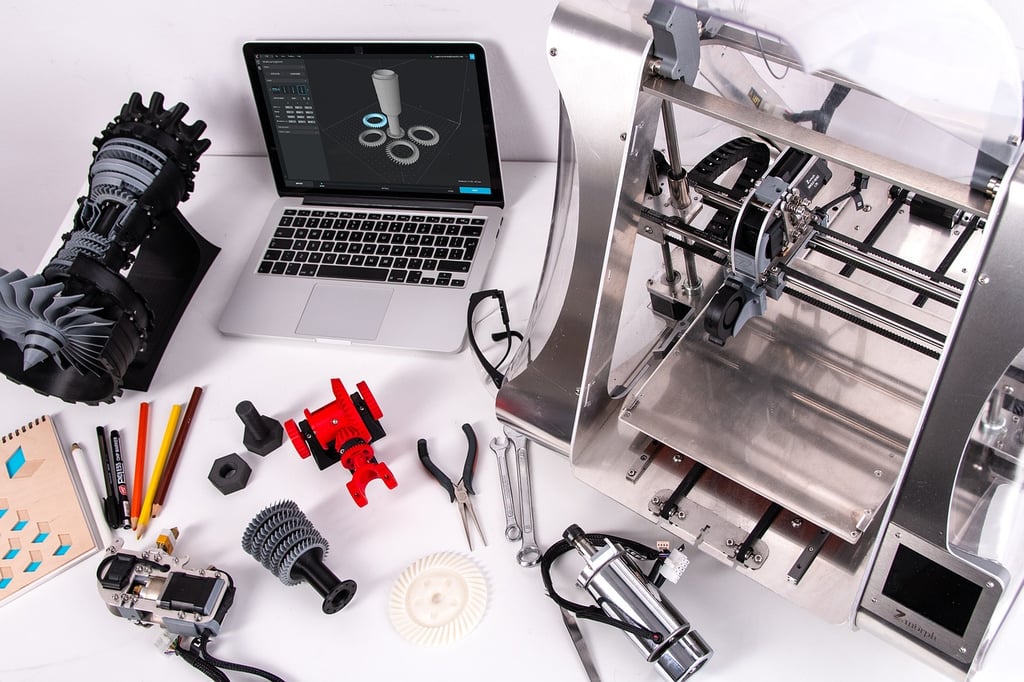

Calibration is a critical step in ensuring the optimal performance of your 3D printer. It involves adjusting various settings and parameters to ensure accurate and precise printing. Proper calibration not only enhances the quality of your prints but also prevents issues like misalignment, uneven layers, and other common printing problems. In this article, we will guide you through the process of calibrating your 3D printer effectively.

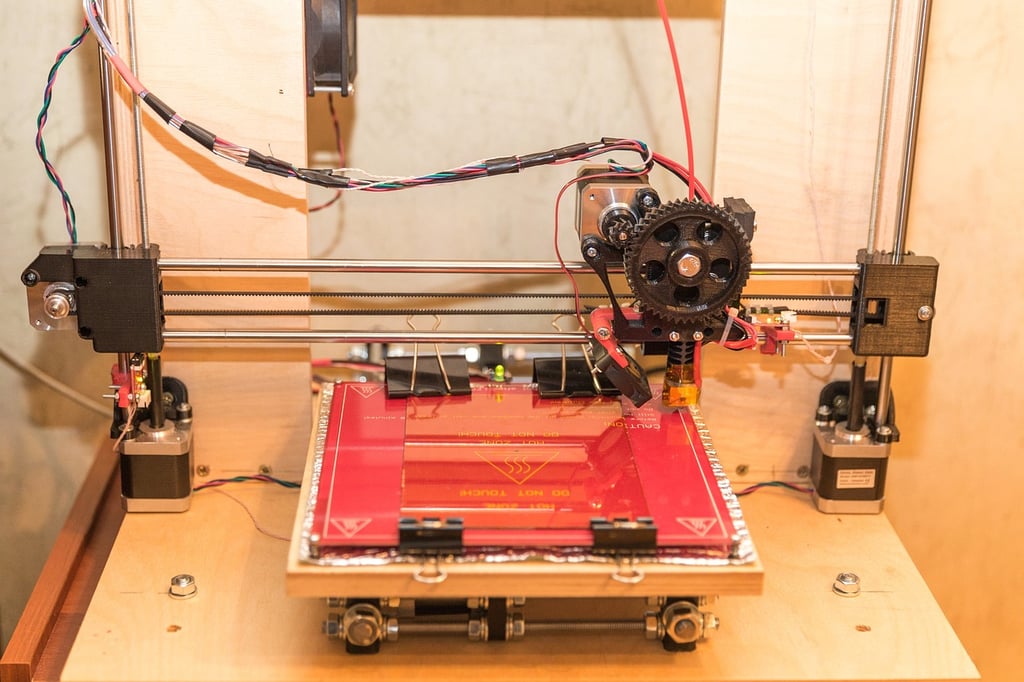

Step 1: Leveling the Print Bed

One of the first and most crucial steps in calibrating your 3D printer is leveling the print bed. A perfectly level bed ensures that the nozzle maintains a consistent distance from the bed throughout the printing process. To level the bed, follow these steps:

1. Home the printer: Start by homing the printer so that the nozzle is at its home position.

2. Adjust the leveling screws: Locate the leveling screws or knobs underneath the print bed. Use a piece of paper or a feeler gauge to gauge the distance between the nozzle and the bed. Adjust the screws or knobs until you achieve the desired levelness. Repeat this process for all corners and the center of the bed.

3. Test the levelness: Once you believe the bed is level, run a test print to confirm. If the first layer adheres uniformly to the bed without any gaps or unevenness, your bed is properly leveled. Otherwise, recheck and readjust as necessary.

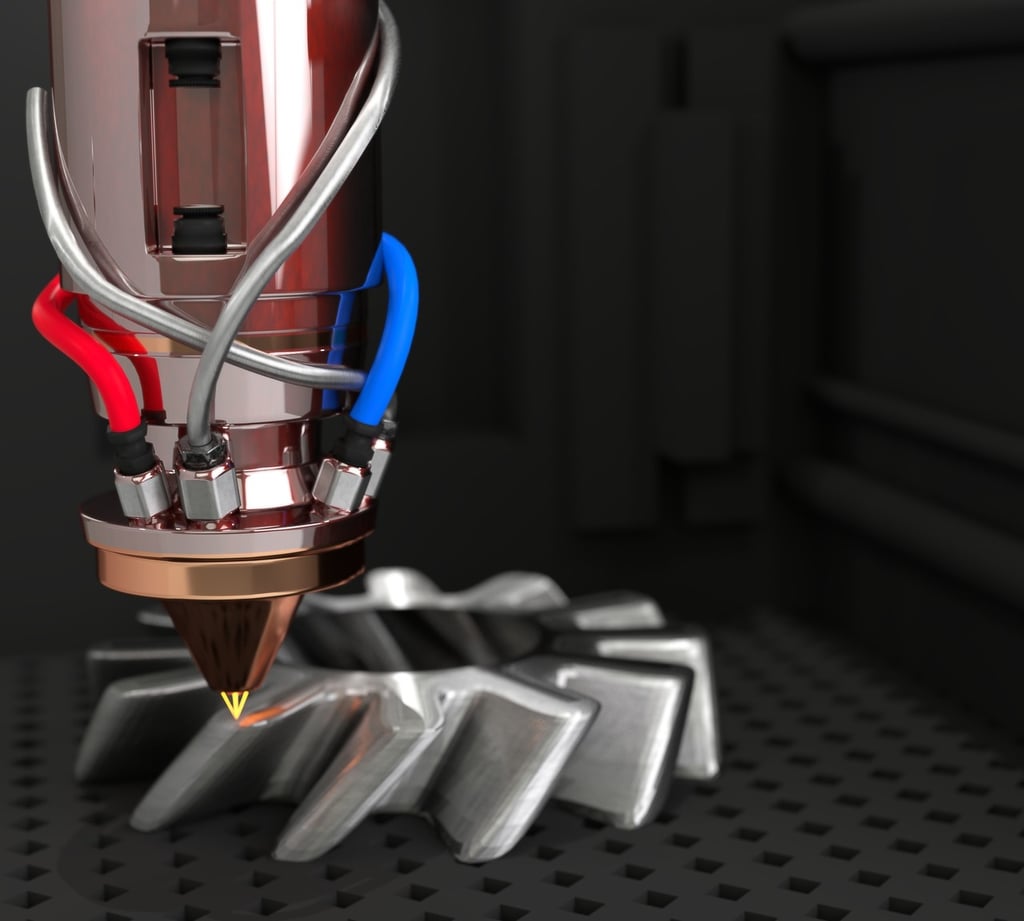

Step 2: Calibrating Extrusion

Extrusion calibration ensures that the printer is pushing out the right amount of filament during the printing process. This calibration is essential for achieving accurate dimensions and preventing issues like over-extrusion or under-extrusion. Follow these steps to calibrate the extrusion:

1. Measure filament diameter: Using a caliper, measure the diameter of your filament at multiple points. Calculate an average value to use for calibration.

2. Adjust extrusion multiplier: In your printer's settings or firmware, locate the extrusion multiplier or flow rate setting. Adjust this value based on your filament diameter measurement. Decrease the multiplier if the filament is over-extruding and increase it if it is under-extruding.

3. Test and fine-tune: Print a calibration cube or a similar test object and inspect the dimensions. Make further adjustments to the extrusion multiplier until you achieve accurate and consistent results.

Step 3: Fine-tuning Temperature Settings

Temperature plays a vital role in the quality and strength of your prints. Different filaments require different temperature ranges for optimal performance. Here's how you can fine-tune your temperature settings:

1. Research optimal temperature range: Consult the manufacturer's recommendations or reliable online sources to determine the recommended temperature range for your specific filament.

2. Test and adjust: Start by printing a temperature tower. This model consists of multiple sections, each printed at a different temperature. Evaluate the quality and strength of each section to identify the optimal temperature. Make note of the temperature where your prints exhibit the best quality.

3. Adjust temperature settings: In your printer's settings, adjust the temperature based on your findings from the temperature tower test. Fine-tune the temperature until you achieve the desired results consistently.

Step 4: Checking Belt Tension and Pulley Alignment

Proper belt tension and pulley alignment are crucial for accurate and smooth movement of the print head. Follow these steps to ensure the correct belt tension and pulley alignment:

1. Inspect belts and pulleys: Check the belts and pulleys for any signs of wear, damage, or misalignment. Ensure the belts are tight but not too tight, with minimal slack.

2. Adjust tension: Locate the belt tension adjustment screws or mechanisms on your printer. Adjust the tension until the belts are firm and have minimal deflection when pushed or pulled.

3. Verify pulley alignment: Observe the movement of the print head as it travels along the belts. Ensure that the pulleys are aligned and not wobbling or slipping. Adjust or replace any misaligned or damaged pulleys as needed.

Conclusion

Calibrating your 3D printer is a crucial step in achieving optimal performance and high-quality prints. By following the steps outlined in this article, you can ensure that your printer is properly calibrated for accurate dimensions, smooth movement, and reliable printing. Remember to periodically recalibrate your printer as environmental factors and wear can affect its performance. Happy printing!

Relative Articles

-

What is an Extruder in 3D Printing?

-

Is 3D Printing Hard? Exploring the Prospects of This Innovative Technology

-

How to Remove Raft from 3D Print: A Step-by-Step Guide

-

How to Clean Up Stringing on 3D Print

-

Can I Pause a 3D Print Overnight? Exploring the Pros and Cons

-

How to 3D Print Large Objects

-

How to Recycle 3D Printer Filament: A Comprehensive Guide

-

How to Make 3D Printer Filament from Plastic Bottles