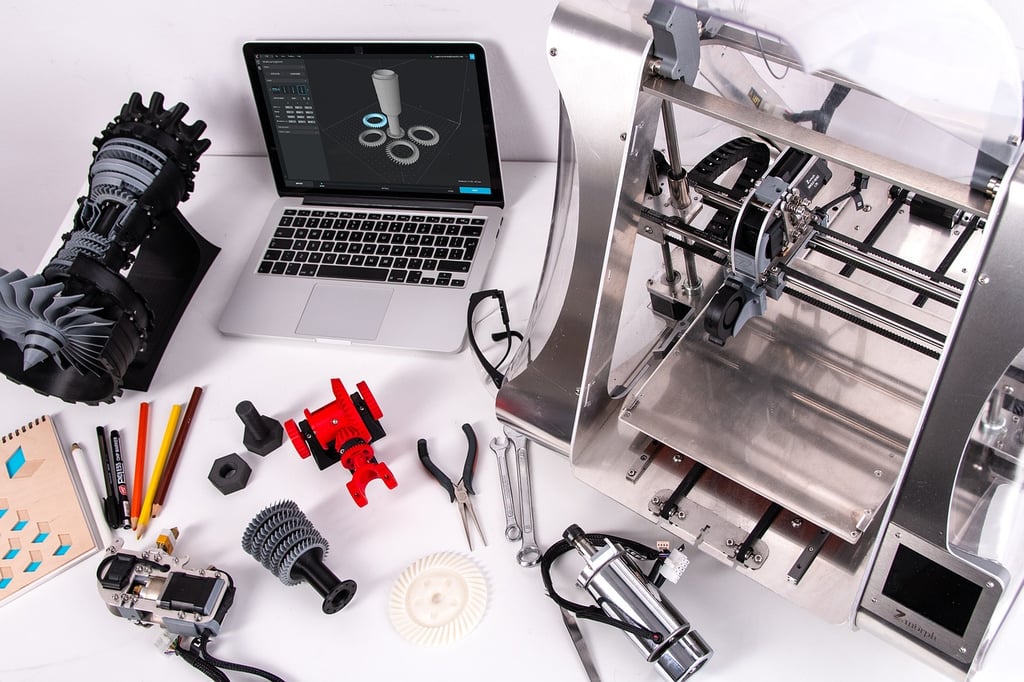

Understanding the Basics of 3D Printing

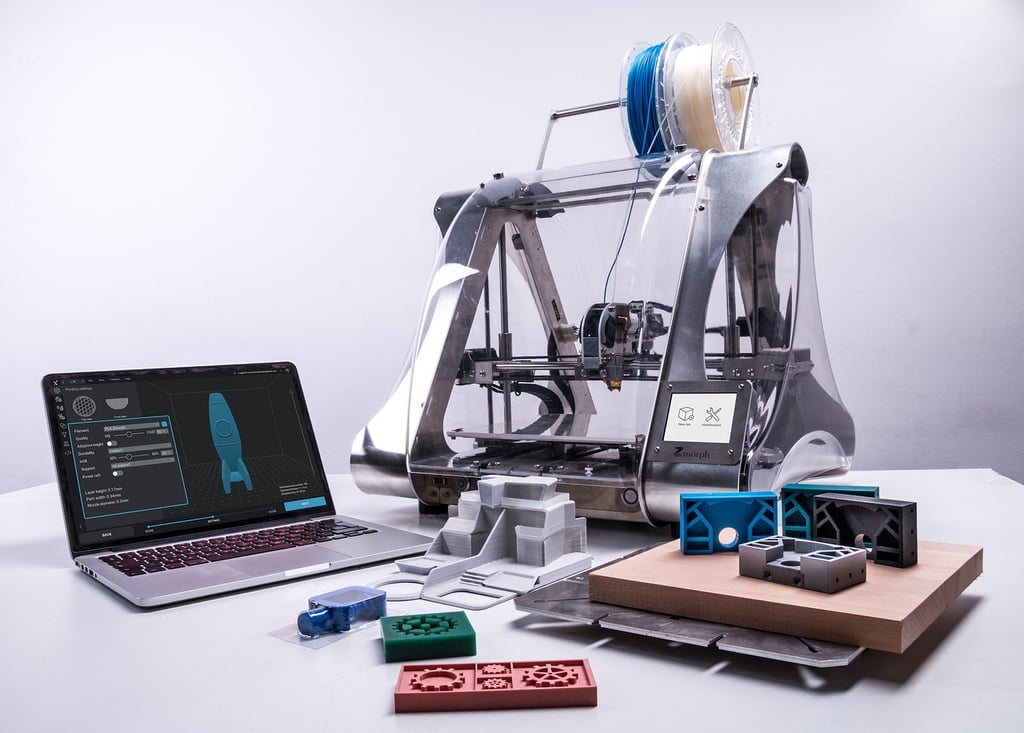

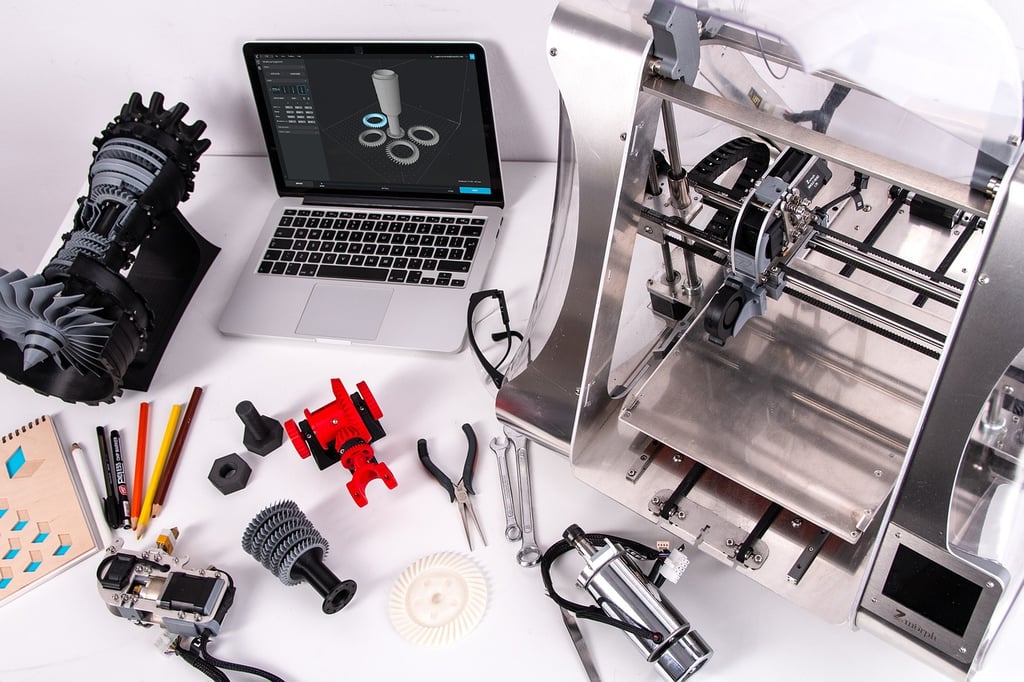

3D printing has revolutionized the way we manufacture objects, allowing for the creation of complex shapes and designs with ease. However, when it comes to printing large objects, there are certain considerations and techniques that need to be taken into account. In this article, we will explore the various aspects of 3D printing large objects and provide you with valuable insights on how to successfully accomplish this task.

Here are the basics you need to know about 3D printing

Understanding of 3D modeling software:

To create a 3D printable object, one needs to have knowledge of 3D modeling software such as Autodesk Fusion 360, Tinkercad, or SolidWorks. This involves understanding the various tools and techniques to design and manipulate 3D objects.

Knowledge of file formats:

3D printers require specific file formats to work with. The most commonly used file format is STL (Standard Triangle Language) which represents the 3D geometry as a collection of triangular polygons. Basic knowledge of file formats and how to convert or export models into the correct format is essential.

Familiarity with slicing software:

Slicing software is used to convert 3D models into a format that the 3D printer can understand. It involves slicing the model into thin layers and generating the necessary toolpath instructions. Understanding how to adjust settings such as layer height, print speed, and infill density is important for achieving desired print quality.

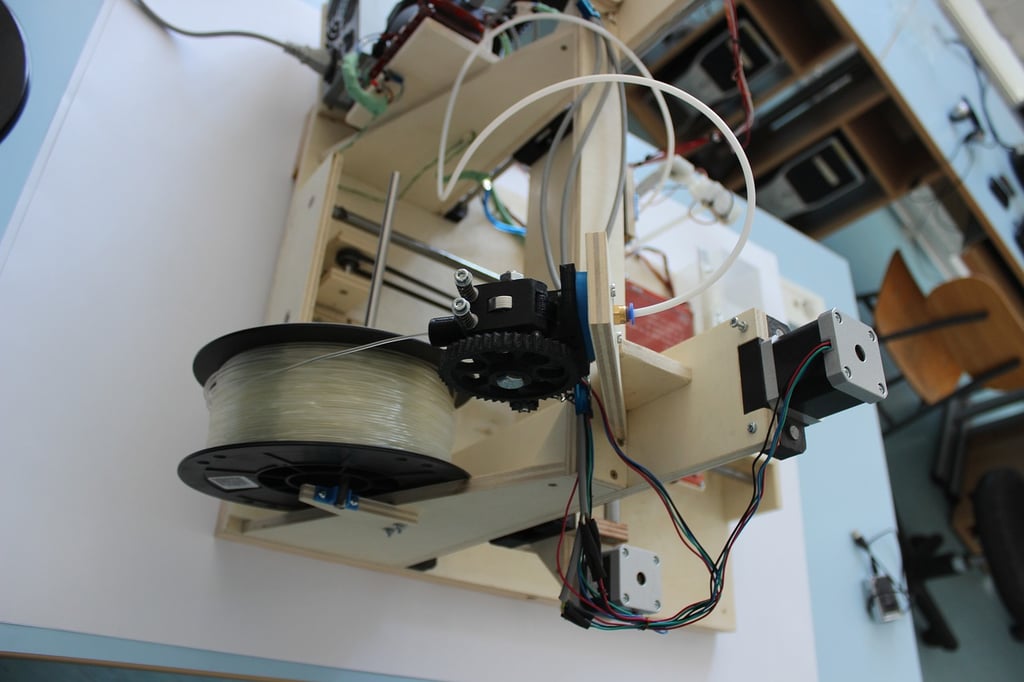

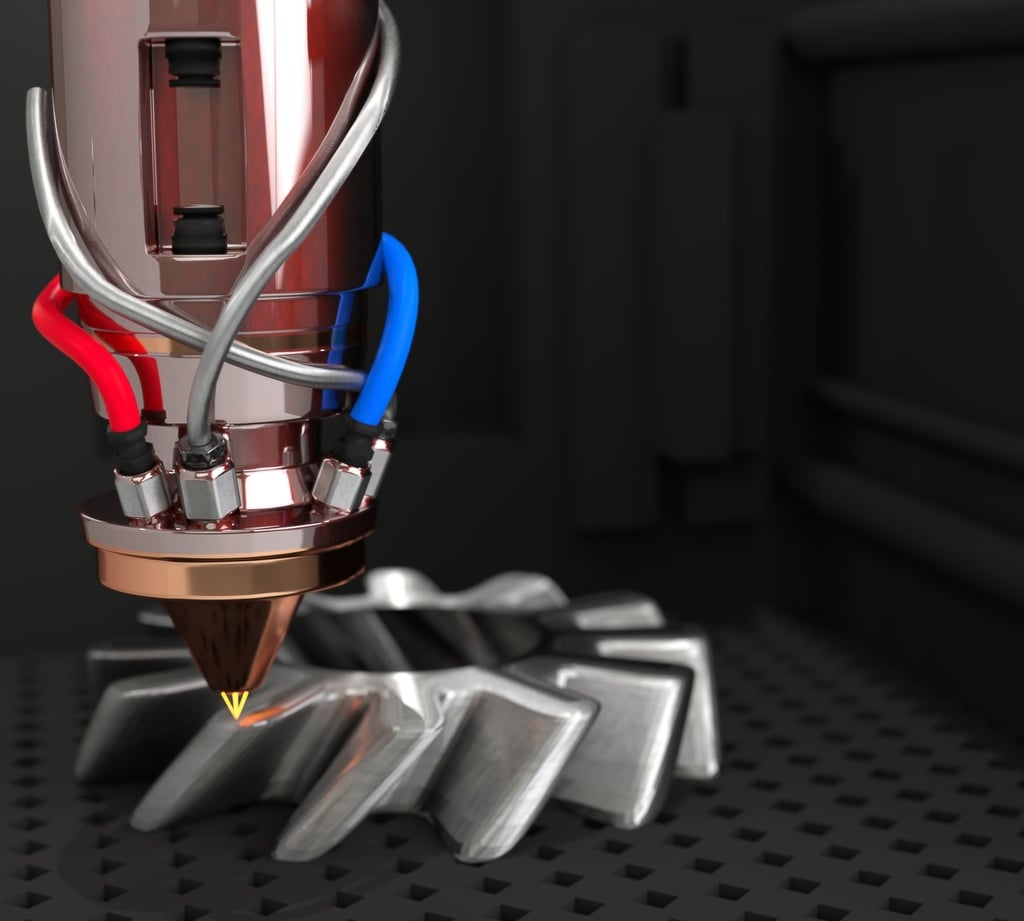

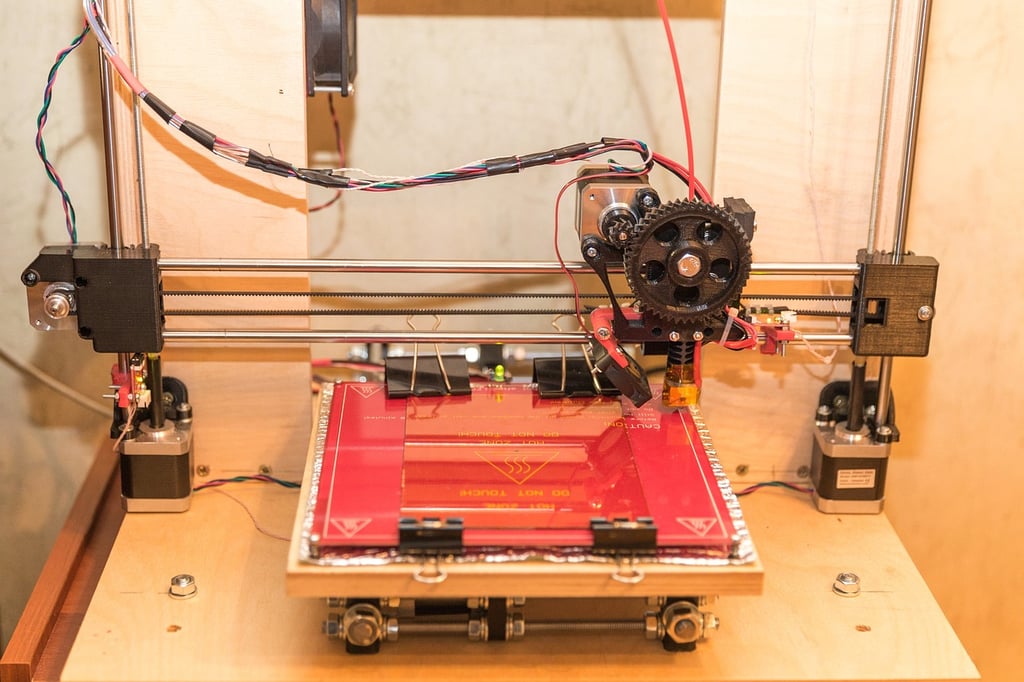

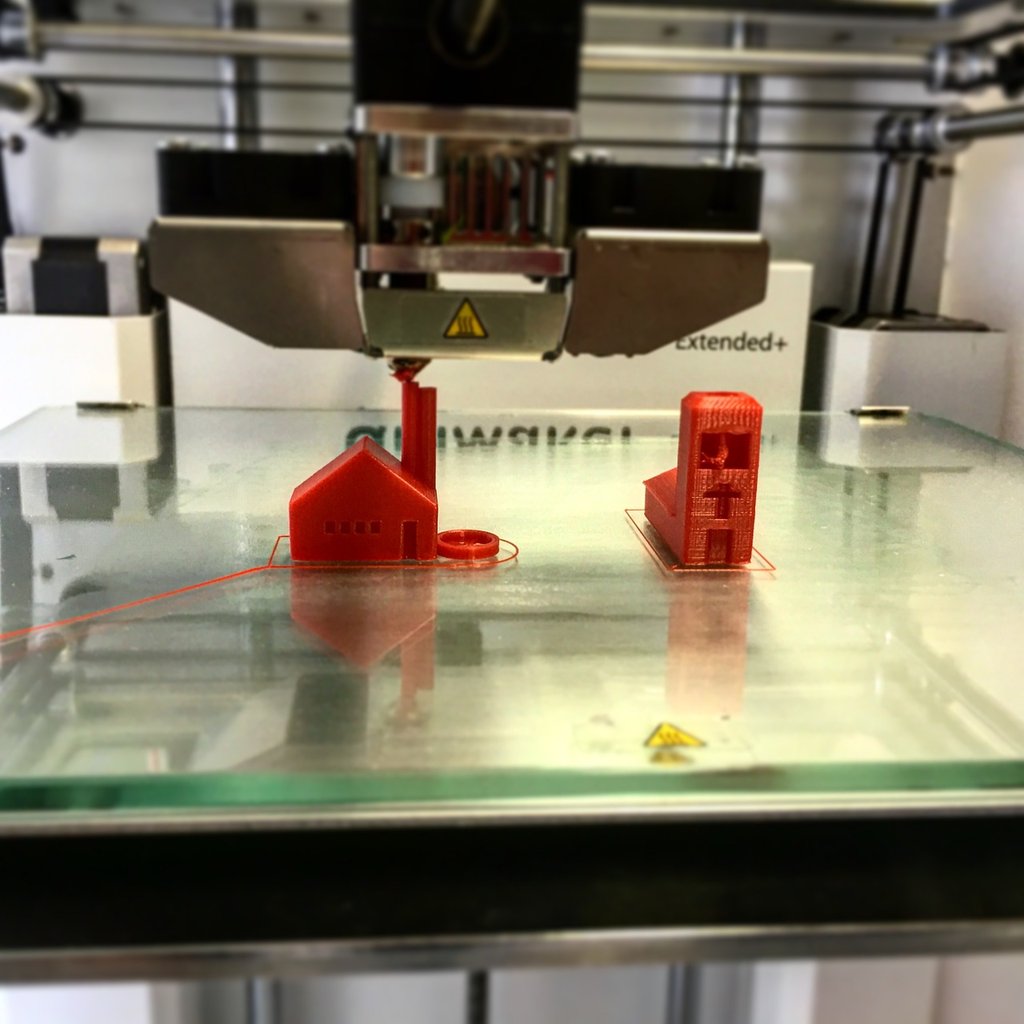

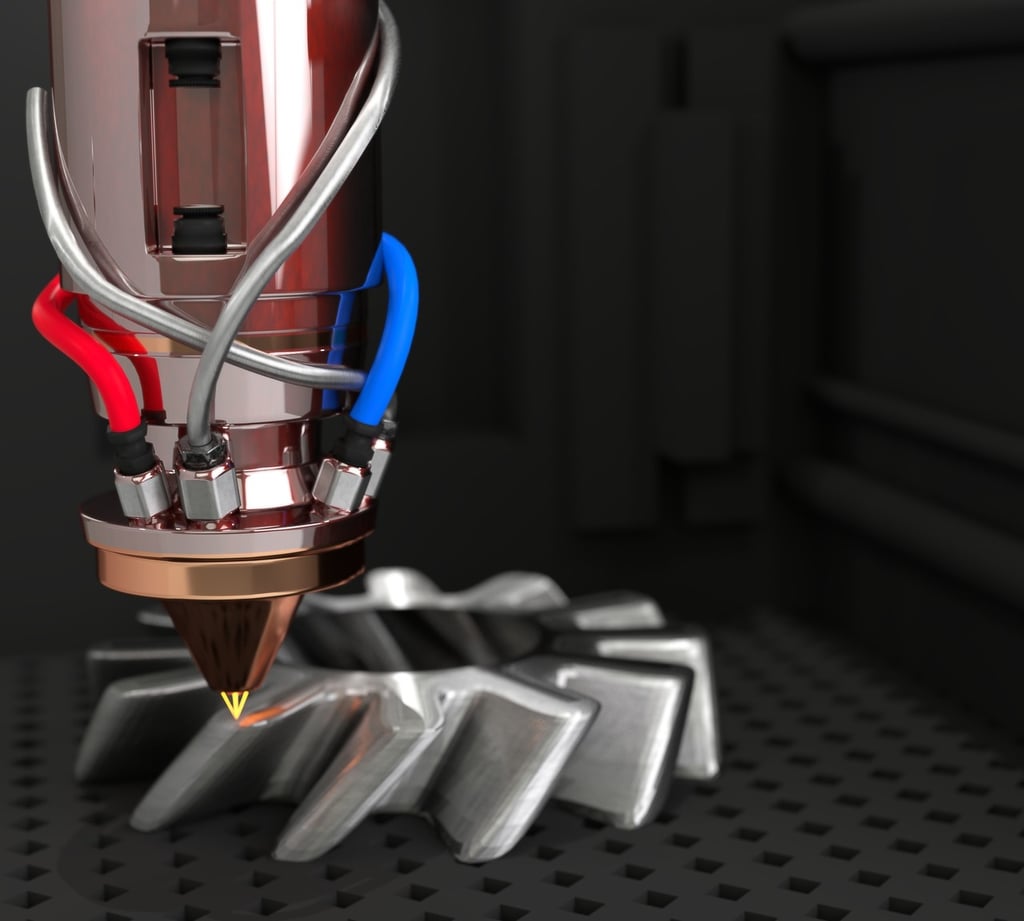

Understanding of 3D printer hardware:

Having basic knowledge of the different components and functionalities of a 3D printer is crucial. This includes knowing about the printer's extruder, heated bed, nozzle size, and filament types. It is also important to understand how to level the bed, calibrate the printer, and troubleshoot common issues.

Knowledge of different filament materials:

There are various types of filaments available for 3D printing, including PLA, ABS, PETG, and more. Understanding the properties of each material, such as strength, flexibility, and temperature resistance, can help in selecting the right filament for specific applications.

Awareness of printing parameters:

Different 3D printing projects may require specific printing parameters. Knowledge of parameters such as layer height, printing temperature, print speed, and support structures is necessary to optimize print quality and achieve desired results.

Post-processing techniques:

3D printed objects often require post-processing to improve their appearance or functionality. Basic knowledge of techniques like sanding, painting, smoothing, or assembling printed parts is important to achieve the desired final product.

Basic troubleshooting skills:

3D printing can encounter various issues, such as failed prints, warping, or clogged nozzles. Having basic troubleshooting skills, such as identifying the source of the problem, adjusting settings, or performing maintenance tasks, can help in resolving issues and ensuring successful prints.

Understanding of design considerations:

Designing for 3D printing requires considering certain factors like overhangs, support structures, tolerances, and build orientation. Understanding these design considerations can help in creating models that are optimized for successful and high-quality 3D prints.

Knowledge of safety precautions:

While 3D printing is generally safe, it is important to be aware of potential hazards such as hot printer components, fumes from certain filaments, and electrical risks. Knowledge of safety precautions, such as using proper ventilation, handling filaments correctly, and adhering to manufacturer guidelines, is essential to ensure a safe and healthy printing environment.

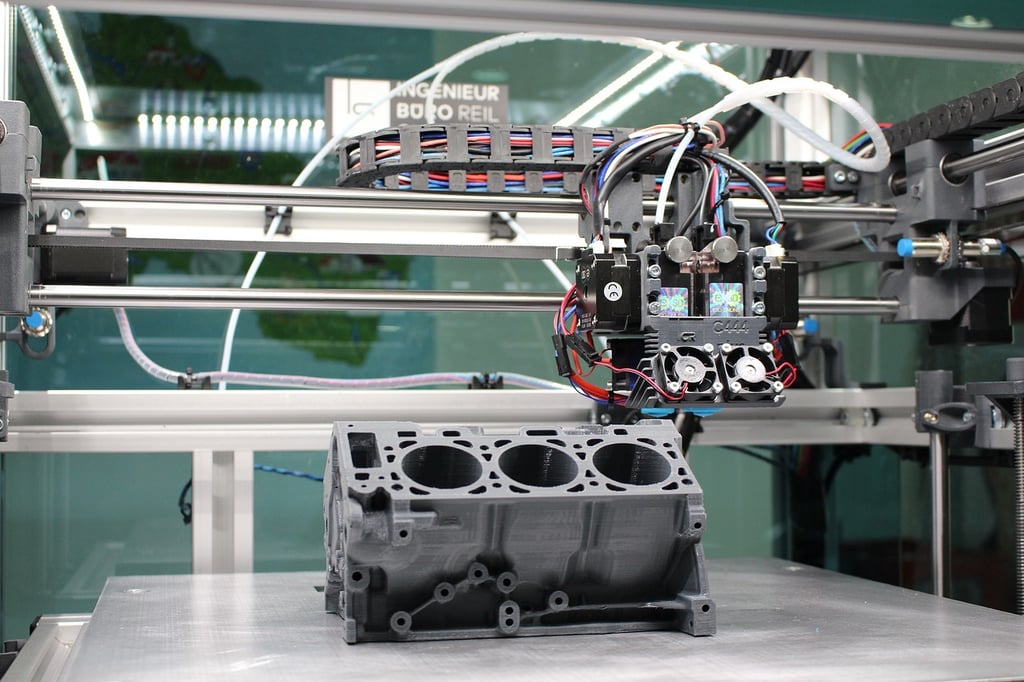

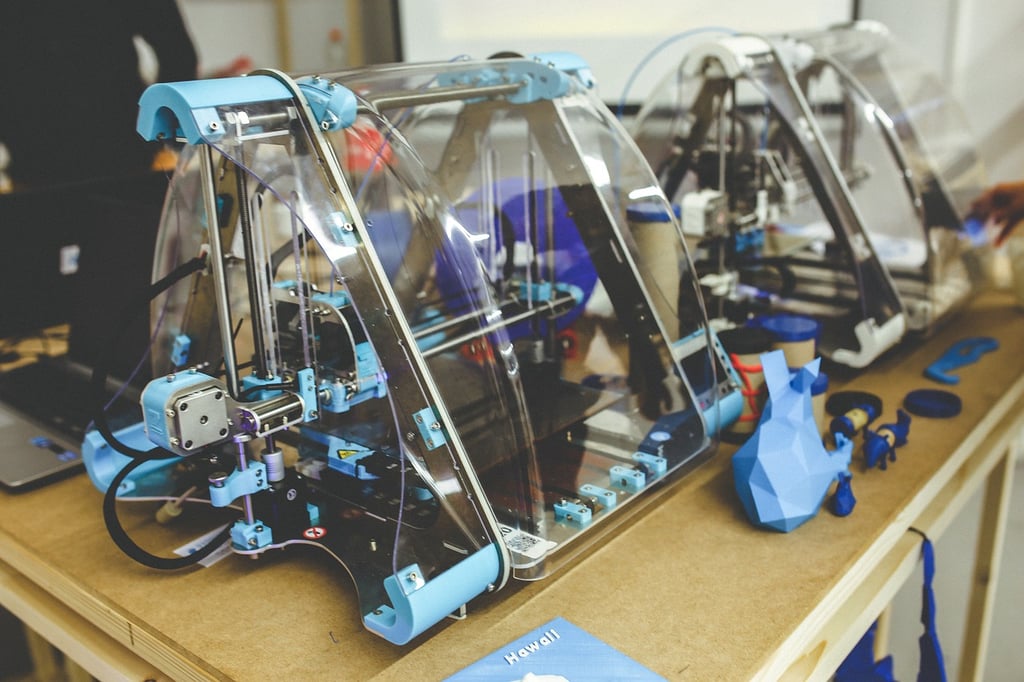

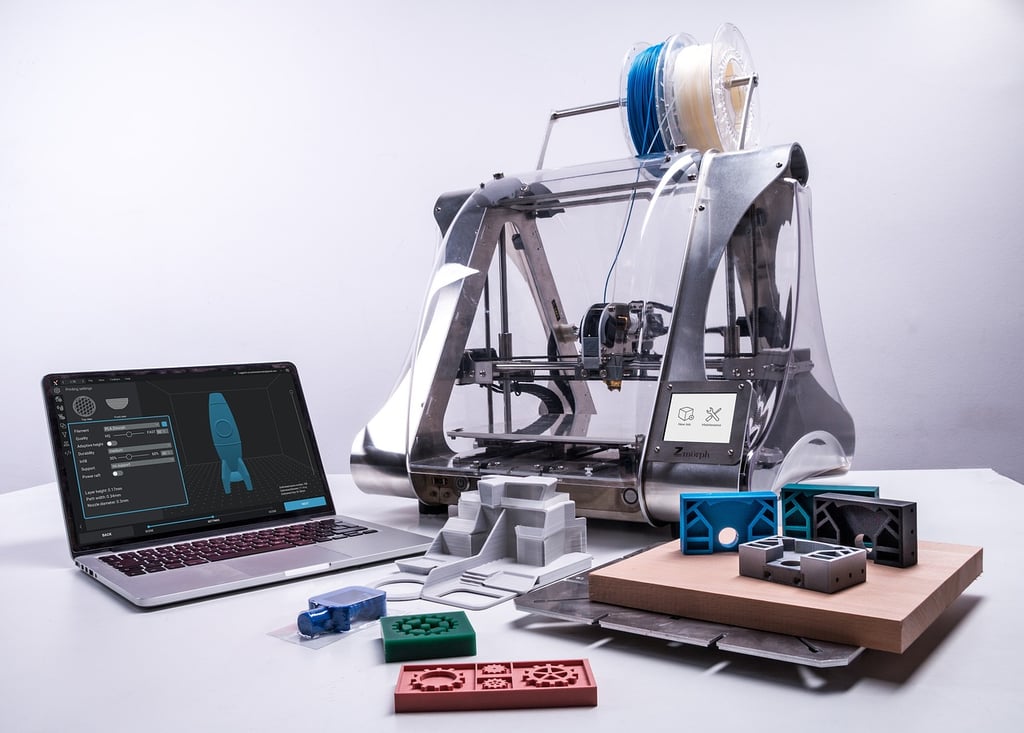

Choosing the Right 3D Printer

Not all 3D printers are created equal, and when it comes to printing large objects, it is crucial to select a printer that can handle the size and complexity of your project. Look for printers with a large build volume, which refers to the maximum dimensions of the object that can be printed. Additionally, consider the printer's layer height capabilities, as larger objects may require thicker layers to ensure stability and reduce print time.

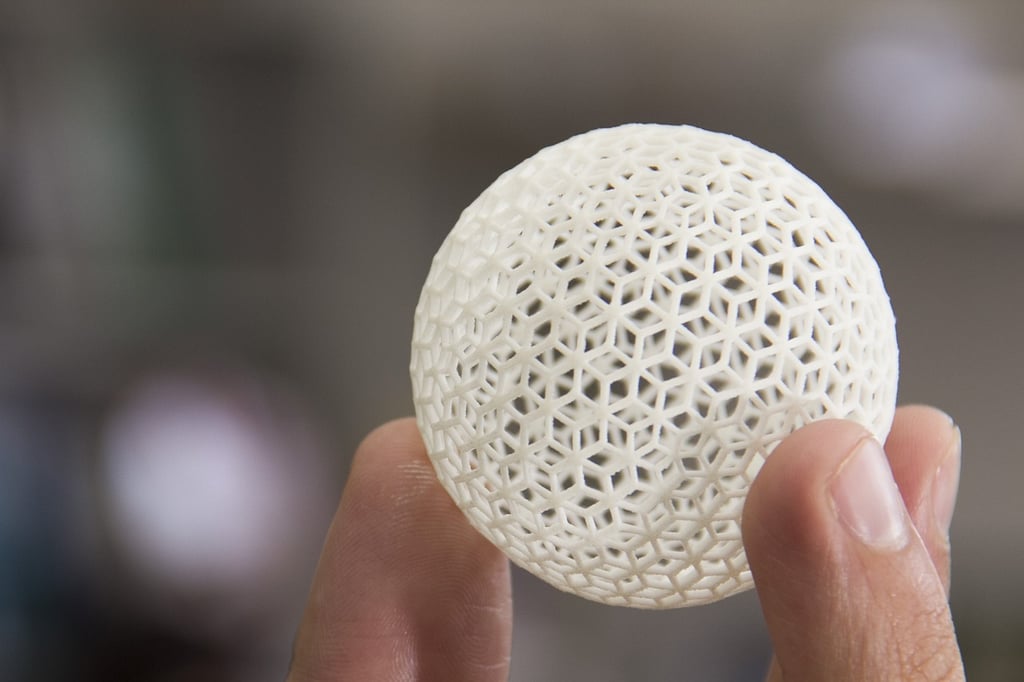

Optimizing Design for Large Prints

Design plays a crucial role in the success of 3D printing large objects. To optimize your design, consider breaking the object into smaller parts that can be printed separately and assembled later. This approach not only reduces the risk of print failures but also allows for greater design flexibility. Additionally, ensure that your design has proper support structures to prevent sagging or collapsing during the printing process.

When 3D printing large objects, it is important to optimize the design to ensure successful and high-quality prints. Here are some tips for optimizing the design for large prints:

Model orientation:

Properly orient the object in the 3D modeling software to minimize the need for supports and ensure better structural integrity. Consider the weight distribution and printing limitations.

Wall thickness:

Increase the wall thickness of the model to provide more stability and strength. A thicker wall will help prevent warping and ensure the print remains intact.

Support structures

If the design requires supports, make sure to add them strategically to minimize material usage and post-processing efforts. Consider adding supports only where necessary to reduce waste and enhance print quality.

Hollowing out the model

For large prints, hollowing out the object can significantly reduce printing time and material usage. However, ensure that the structure remains sturdy and retains its integrity during the printing process.

Slice the model

Divide the model into smaller parts for printing and then assemble them later. This approach can help overcome size limitations and reduce the chances of print failure.

Filament choice

Select a filament appropriate for large prints, such as PLA or ABS, which provide good strength and dimensional stability. Consider using filament with larger diameter to speed up the printing process.

Cooling and ventilation

Large prints generate a significant amount of heat, which can affect print quality. Ensure proper cooling and ventilation during the printing process to avoid warping and ensure consistent layer adhesion.

Print bed adhesion

Use a suitable print bed adhesive, such as painter's tape, glue stick, or specialized bed adhesion solutions, to ensure proper adhesion and minimize warping.

Print settings

Adjust the print settings such as print speed, layer height, and infill density to optimize the print quality and reduce the chances of print failure. Experiment with different settings to find the optimal balance.

Post-processing considerations

Plan for post-processing steps such as sanding, painting, or smoothing to enhance the final appearance and functionality of the large print.

By following these tips, you can optimize your design for large prints when 3D printing large objects, leading to successful and high-quality prints.

Choosing the Right Filament

The choice of filament is another important factor to consider when 3D printing large objects. Different materials have varying properties, such as strength, flexibility, and heat resistance. For large prints, it is recommended to use materials with high dimensional stability, such as ABS or PETG, as they are less prone to warping or shrinking. Additionally, consider the filament's diameter, as thicker filaments can reduce print time and increase the strength of the final object.

Here are some factors to consider when selecting the filament:

Material:

Determine the material that suits your requirements and the intended use of the object. Common filament materials include PLA, ABS, PETG, and TPU. PLA is easy to print with and offers good strength, while ABS is more durable and heat-resistant. PETG combines the best of both worlds, providing strength and flexibility. TPU is ideal for objects requiring elasticity.

Filament diameter:

Check the filament diameter compatibility with your 3D printer. The most common diameters are 1.75mm and 2.85mm. Ensure that your printer can handle the chosen filament size.

Strength and durability:

Consider the strength and durability needed for your application. If the object will be subjected to stress or heavy loads, choose a filament with higher strength and durability, such as ABS or PETG.

Heat resistance:

If the object will be exposed to high temperatures, select a filament with good heat resistance, like ABS or PETG. PLA has a lower heat resistance and may deform under high temperatures.

Printability:

Evaluate the filament's printability characteristics. Some filaments, like PLA, are easy to print with and require less calibration compared to others. ABS, on the other hand, may require a heated bed and an enclosed chamber to prevent warping.

Cost:

Consider the cost of the filament. Different filaments have varying prices. While some materials may be more expensive, they may offer better performance or specific properties for your large 3D object.

Color and aesthetics:

Choose a filament color that suits your preference or the desired appearance of the object. Some filaments also offer unique textures or finishes, allowing you to add a distinctive touch to your prints.

Reviews and recommendations:

Read reviews and recommendations from experienced 3D printer users or online forums. This can provide insights into the filament's performance, printability, and suitability for large prints.

Remember to always check your 3D printer's specifications and capabilities before selecting a filament. Testing different filaments and adjusting print settings may also be necessary to achieve the desired results when printing large objects.

Optimizing Print Settings

When printing large objects, it is crucial to optimize the print settings to achieve the best possible results. Start by adjusting the print speed, as slower speeds can improve print quality and reduce the risk of errors. Additionally, consider increasing the infill percentage, which refers to the density of the internal structure of the object. Higher infill percentages can enhance the strength and stability of large prints.

Here are some tips for optimizing your design and print settings:

Model optimization

Start by optimizing your 3D model for large prints. This involves reducing unnecessary details and simplifying the geometry. Remove any fine details that may not be noticeable in the final print. Simplifying the model will help to reduce the overall file size and improve the printing process.

Print orientation

Choosing the right print orientation is crucial for large prints. Experiment with different orientations to minimize support material and achieve the best surface quality. Consider the stability and strength of the printed object when deciding on the orientation.

Layer height

Adjust the layer height in your 3D printer settings. For large prints, it is recommended to use a thicker layer height to speed up the printing process. However, keep in mind that a thicker layer height may result in a less detailed print.

Infill density

Adjust the infill density to strike a balance between structural integrity and material usage. For large prints, a lower infill density can be used to save material and reduce print time. Experiment with different infill patterns and densities to find the optimal setting.

Print speed

Increase the print speed for large prints to reduce the overall print time. However, make sure not to compromise the print quality. It is recommended to gradually increase the print speed and monitor the print quality until you find the optimal speed.

Cooling settings

Adjust the cooling settings to prevent warping and improve the overall print quality. Cooling is especially important for large prints as they tend to generate more heat during the printing process. Use cooling fans or adjust the fan speed to ensure proper cooling.

Support structures

Implement support structures only where necessary to minimize material usage and post-print cleanup. Large prints may require some support structures, but try to minimize their use to reduce print time and material consumption.

Print bed adhesion

Ensure proper bed adhesion by using adhesive aids such as a heated bed, adhesion sprays, or tapes. Large prints are prone to warping and detachment from the print bed, so ensuring good adhesion is crucial.

Print environment

Maintain a controlled print environment to minimize temperature fluctuations. Large prints are more susceptible to temperature changes, which can affect the print quality. Use an enclosure or cover the printer to create a stable environment.

Pre-print checks

Before starting the print, thoroughly inspect the 3D printer for any mechanical issues. Ensure that the printer is properly calibrated, belts are tightened, and there are no clogs or obstructions in the extruder. A well-maintained printer will yield better results for large prints.

Remember, optimizing design and print settings for large prints may require some trial and error. It's important to experiment and iterate to achieve the best possible results.

Post-Processing and Finishing Touches

Once the printing process is complete, it is important to properly post-process and finish your large 3D prints. This may involve removing support structures, sanding rough edges, and applying paint or other coatings to enhance the appearance of the object. Take your time to carefully inspect and clean the print, ensuring that all parts fit together correctly and that any imperfections are addressed.

3D printing, large objects, 3D printer, design optimization, filament choice, print settings, post-processing

How to 3D Print Large Objects - A Comprehensive Guide

Learn how to successfully 3D print large objects with this comprehensive guide. Discover the best practices for design optimization, filament choice, and print settings to achieve stunning results.

Relative Articles

-

What is an Extruder in 3D Printing?

-

Is 3D Printing Hard? Exploring the Prospects of This Innovative Technology

-

How to Remove Raft from 3D Print: A Step-by-Step Guide

-

How to Clean Up Stringing on 3D Print

-

How to Calibrate Your 3D Printer for Optimal Performance

-

Can I Pause a 3D Print Overnight? Exploring the Pros and Cons

-

How to Recycle 3D Printer Filament: A Comprehensive Guide

-

How to Make 3D Printer Filament from Plastic Bottles